JH-3D Prototype

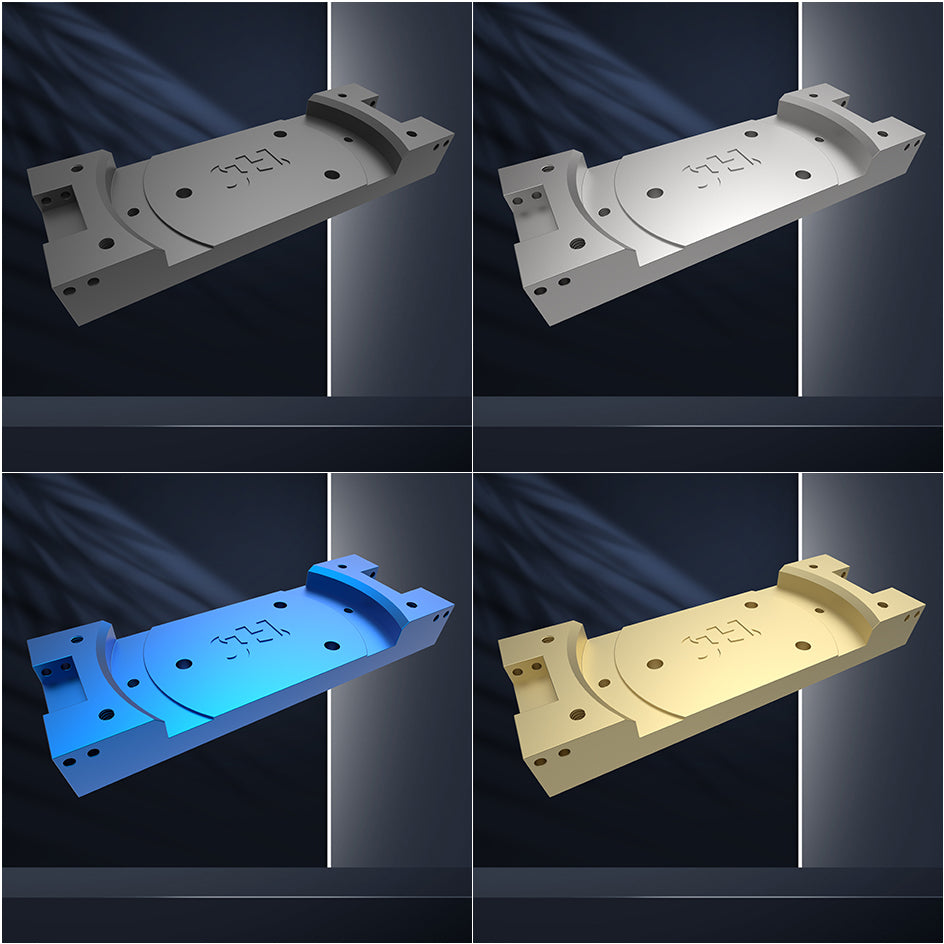

Customized CNC Machining Service High Precision Batch Mass Production Plastic ABS Nylon Metal Aluminum Stainless Brass Copper Parts

Customized CNC Machining Service High Precision Batch Mass Production Plastic ABS Nylon Metal Aluminum Stainless Brass Copper Parts

Couldn't load pickup availability

Note

This is a link just to show our CNC machining technologies and materials, please do not order directly.

If you have any requirements for cnc machining parts, please kindly contact us.

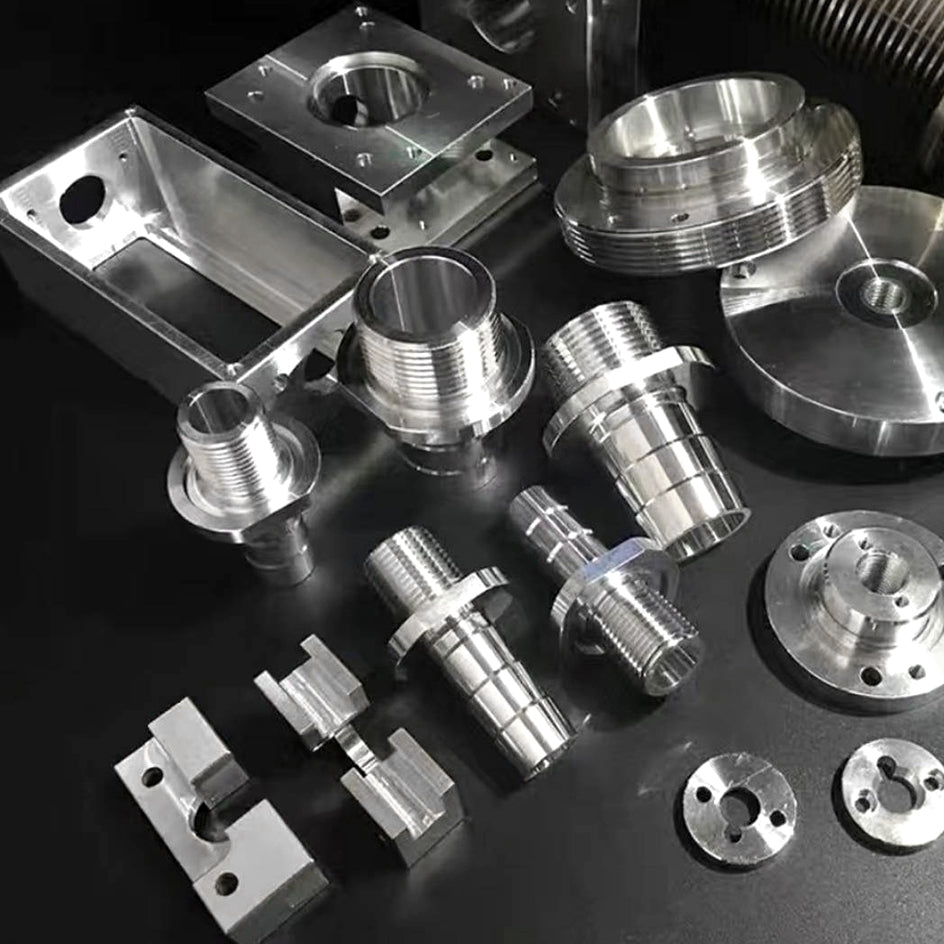

Customized CNC machining parts

Your Desing, Our Precision - CNC Craftsmanship

PLASTIC/ MESTAL/PVC

About CNC machining

What is CNC Machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process in which pre-programmed computer software dictates the movement of machinery and tools. This process is used to control a wide range of complex machinery, from grinders and lathes to mills and routers. CNC machining is commonly used in manufacturing and industrial settings to create precise, intricate, and repetitive parts or products.

How does CNC machining works?

1.Design: The process starts with a CAD model of the part or product to be manufactured. This digital design is essential because it dictates the dimensions, specifications, and geometry of the final product.

2.Programming: Once the CAD model is ready, CNC programmers create instructions using CAM software. These instructions are essentially a set of precise coordinates and movements that the CNC machine will follow to create the desired part.

3.Machine Setup: The programmer or operator loads the CAD file and CNC program into the CNC machine. They also install the appropriate cutting tools, materials, and fixturing.

4.Machining: The CNC machine executes the programmed instructions, cutting and shaping the raw material (such as metal, plastic, or wood) into the final part. The machine's movements are highly precise and can include cutting, drilling, milling, turning, and other operations.

5.Quality Control: Throughout the machining process, operators may perform quality checks to ensure that the dimensions and tolerances are within the specified range.

What is the advantages of CNC Machining?

1.Precision: CNC machines can achieve extremely high levels of precision and accuracy, making them ideal for complex and intricate parts.

2.Repeatability: Once a program is created, the same part can be reproduced consistently with minimal variation.

3.Efficiency: CNC machining can be faster and more efficient than traditional manual machining methods.

4.Versatility: CNC machines can work with a wide variety of materials, from metals to plastics to composites.

5.Complexity: They can create parts with intricate geometries that would be difficult or impossible with manual machining.

6.Industries such as aerospace, automotive, medical, electronics, and many others rely heavily on CNC machining for producing parts and components used in their products.

What is the disadvantages of CNC Machining?

1.Programming Complexity: Creating CNC programs can be complex, especially for intricate parts. Skilled programmers are needed to generate efficient toolpaths and programs, which can add time and cost to the manufacturing process.

2.Limitation on Small Batch Sizes: While CNC machining is excellent for large production runs and repetitive tasks, it may not be as cost-effective for small batch sizes. The setup time and programming required for each job can make small runs less economical.

3.Material Limitations: While CNC machines can work with a wide range of materials, certain materials, such as ceramics and some composites, can be challenging to machine. Specialized equipment and tooling may be required.

4.Not Ideal for Prototyping: Creating prototypes with CNC machining can be expensive and time-consuming, especially if design changes are needed. Rapid prototyping methods like 3D printing might be more suitable for quick iterations and design validation.

5.Risk of Automation Errors: As CNC machines are automated, there is a risk of errors if the programming or setup is incorrect. These errors can lead to scrap parts and wasted materials.

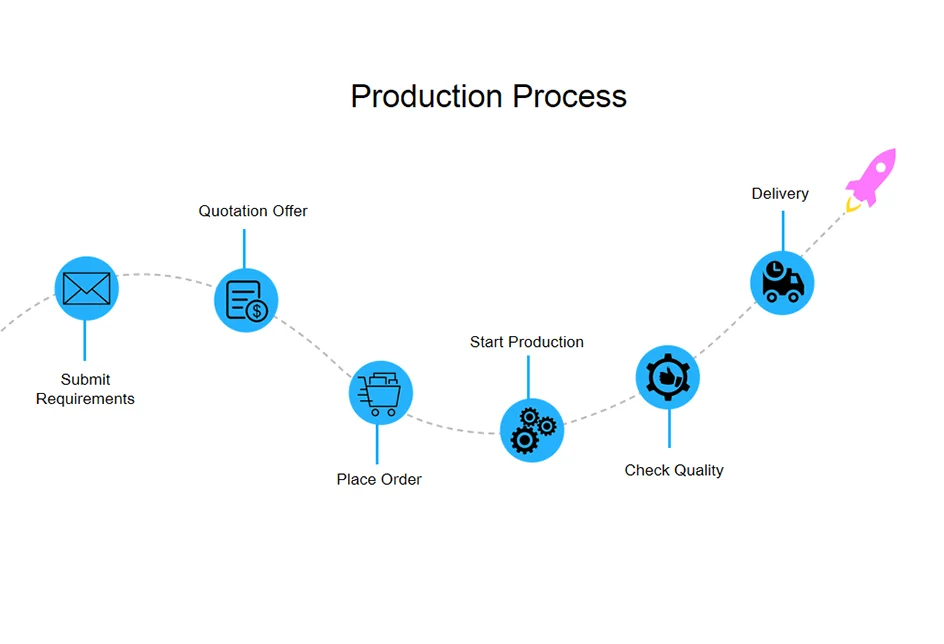

How to order

1, Send us your requirement

2, Quotation offer

3, Place order

4, Start Production

5, Check Quanlity

6, Ship and Delivery